world steel hardness test|rockwell hardness wikipedia : exporter When I first saw this thing, I thought it was the most ridiculous idea ever. Then I tried it a few times and realized it really isn’t half bad. It’s meant to be a highly portable hardness check. To . See more WEBDescription. Watch, stream and download Juju Furacão do cuckold at PornOne for free. This juju porn video is related to Big Dick, Cuckold and Straight. It was uploaded by .

{plog:ftitle_list}

webSérgio Sacani Sancevero [2] (Londrina, 17 de setembro de 1975), é um geofísico, youtuber, podcaster e proeminente divulgador científico brasileiro, dono do blog Space Today e .

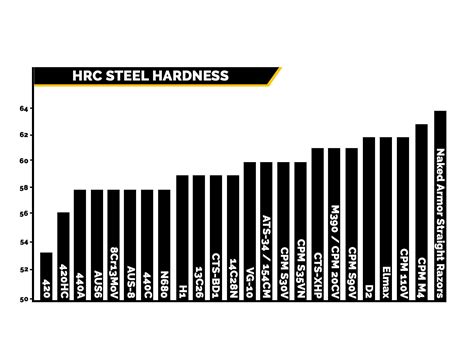

rockwell steel hardness scale

This is probably the most common way of professionally and accurately checking the hardness of metals. A rounded steel ball or conical diamond tip is pushed into the metal, and the depth of the indent is measured by the machine. The machine uses a minor load and a major load to make sure that the reading is . See moreYou might have heard about this in school, that you can get a ball bearing, whack it with a hammer on a piece of metal with a known hardness, . See moreThis is really interesting. The most common microhardness are Vickers and Knoop. In real life, I’ve come across Vickers far more . See more

This is the classic, easy way that bladesmiths use to check if their heat treating worked. The concept itself is really simple: If a cutting . See moreWhen I first saw this thing, I thought it was the most ridiculous idea ever. Then I tried it a few times and realized it really isn’t half bad. It’s meant to be a highly portable hardness check. To . See more

extech moisture meter pins

The Mohs Hardness Scale is a widely recognized and simple scale for measuring the scratch resistance of various minerals. Created by Friedrich Mohs, a German geologist, in 1812, it remains a standard in geology, .Mohs hardness kit, containing one specimen of each mineral on the ten-point hardness scale. The Mohs scale (/ m oʊ z / MOHZ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of .

The indenter used in the Brinell hardness test is usually a hardened steel or carbide ball. There are four sizes of the indenter used for the Brinell hardness test. They are 1 mm, 2.5 mm, 5 mm, and 10 mm in size. . This website is my . This article explores the fascinating world of stainless steel hardness testing. You’ll learn about the different methods used, including Brinell, Rockwell, and Vickers tests, and discover why hardness testing is becoming . In this blog post, we'll dive into the fascinating world of hardness testing and explore the different scales used to measure a material's resistance to deformation. . (HB) exceeds 450 or the sample is too small, the Rockwell hardness test is used instead. This test involves pressing a diamond cone with a 120° top angle or a steel ball (1 .

Mohs hardness test: . a steel file a streak plate a piece of quartz: Mohs Hardness of Common Objects: Fingernail: 2 to 2.5: Copper sheet: 3: Nail . The Mohs scale has stood the test of time and has been widely used throughout the world for over 200 years - mainly because it is easy-to-do, inexpensive, and people quickly understand it. . In this article, we’ll explore the fascinating world of material hardness, from talc to diamond. You’ll learn how different tests, like Brinell, Rockwell, and Vickers, measure this crucial property, and why it matters in engineering. . Hardness symbol; 10 – Diameter of steel ball mm; 3000 – Load size kgf; 30 – Load holding time s .Also hardness ranges for heat treated steel. Online shop Contact. Regional Depots. Bristol: 0117 403 1441 Exeter: 01392 790 275 Inverness: 01463 572 078 Isle of Wight: 01983 640 018 Glasgow: 0141 370 2331 Maidstone: 01622 963 030 Manchester: 0161 641 3700 .The connection between hardness and carbon content is clearly visible in the example below: the higher the carbon content, the higher also the HRC of various types of White Steel: White Steel 1 / 63 HRC / C = 1.25-1.35 % White Steel 2 / 61-62 HRC / C = 1.05-1.15 % White Steel 3 / 60 HRC / C = 0.80-0.90 % Measuring hardness There are several .

4140 steel hardness: Cooling/Agent: Normalizing: 870 (1600) 302 HB: Air: Annealing: 790-845 (1455-1555) 197 HB: Furnace cooling: Quenching: 830-845 (1525-1555) Oil: Tempering (2 hour) 205 (400) . The World Material is a website mainly provides the information of worldwide material grades, including US ASTM AISI SAE, European EN, British BS .

Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter . Steel is one of the most useful materials in the world. In the simplest context, steel is composed of iron and carbon, but in actuality, steel isn’t so simple. . Tool steel is a type of steel alloy whose hardness, resistance to abrasion, and ability to retain shape at increased temperatures make it a popular choice for hand tools and .By World Material. Share Facebook Twitter . Room temperature hardness, HRC: Test temperature, °C (°F) Tensile strength, MPa (ksi) . H13 steel hardness range is 28-53 HRC varies with tempering temperature, all specimens are air-cooled from 1025 °C (1875 °F) and tempered at temperature for 2 hours.

The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded.The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10 . Brinell hardness test is an indentation hardness test. It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the .

Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and yIt is a versatile test, suitable for a wide range of materials, including thin and brittle materials. You can explore more details about the Vickers hardness tester in our ultimate guide. 2. Brinell Hardness Test. The Brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the material.

rockwell steel hardness chart

rockwell hardness wikipedia

Development of Janka Wood Hardness Scale The Brainchild of Gabriel Janka. The Hardness Test was developed by Austrian-born American wood researcher Gabriel Janka (1864-1932). Janka’s ingenious method allowed for a more systematic approach to understanding relative hardness of wood, a critical factor that influences the wood’s longevity and suitability for .

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials . This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test Discover the world's research 25+ million members The first widely accepted and standardized indentation-hardness test was proposed by J. A. Brinell in 1900. Brinell’s interest in materials science grew during his involvement in a several Swedish iron companies and his desire to have a consistent and fast means of determining material hardness.Steel hardness is a critical parameter that directly influences a material's performance in various applications. Different scales, such as Rockwell C (HRC), Brinell (HB), Vickers (HV), and Rockwell B (HRB), are employed to quantify the hardness of steel and other metals. Each scale offers unique insights into a material's mechanical properties .

The Leeb Hardness Test, also known as the rebound hardness test, measures hardness by analyzing the rebound of an indenter, rather than the size of an indentation. It is portable and ideal for on-site testing of large and heavy components, offering a non-destructive method that causes minimal damage to finished parts and coatings. Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5)

The ability to accurately and efficiently test the hardness of materials is a priority for academic research laboratories worldwide, as universities seek to provide students with the real-world skills demanded by materials science and engineering positions. However, the complex and diverse range of hardness testing procedures — such as .The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO 6506, ISO 6507, ISO 45452, ASTM E384, ASTM E92, ASTM E10, ISO 6508, ASTM E18, DIN 51917 and ISO 2039 standards. The DuraVision .

extech moisture meter price

WEBDiscover videos related to ana catarina paolino pelada on Kwai

world steel hardness test|rockwell hardness wikipedia